Design

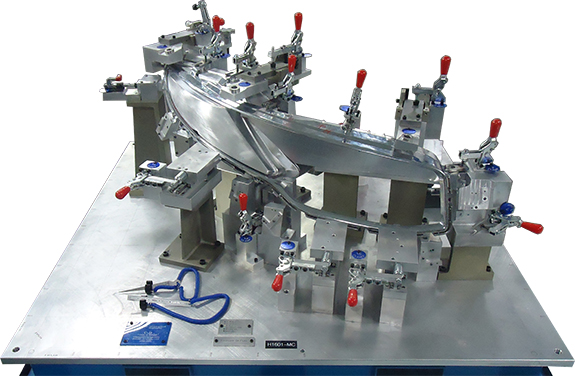

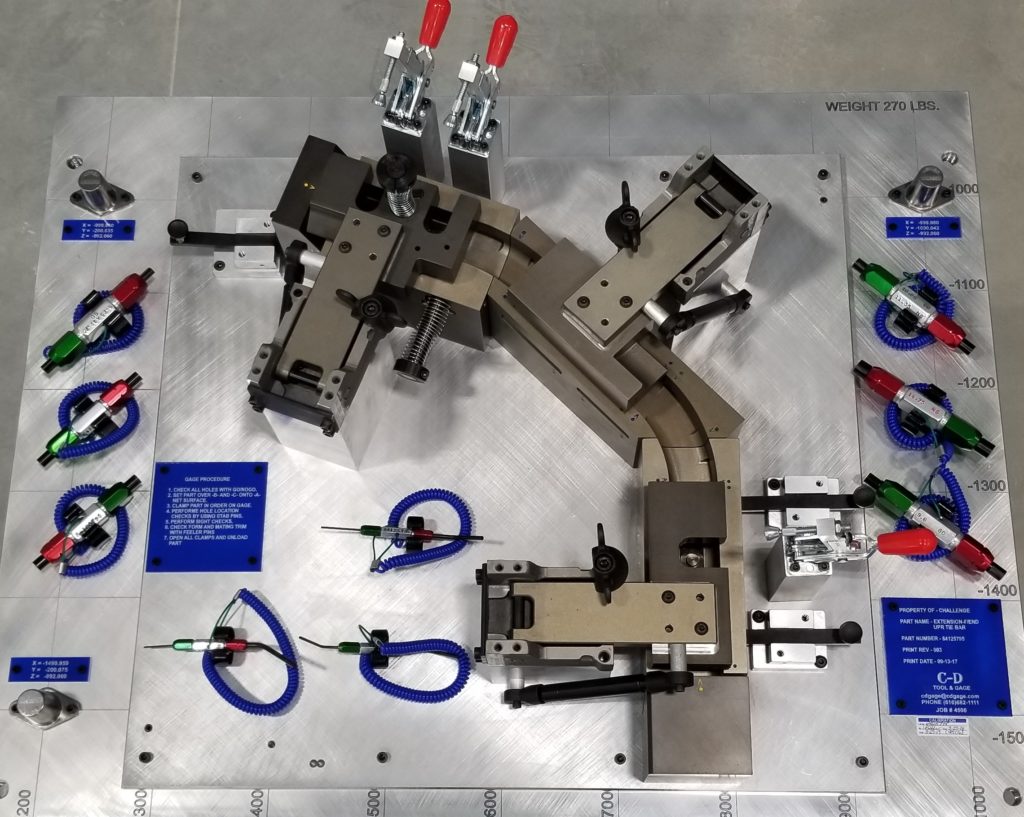

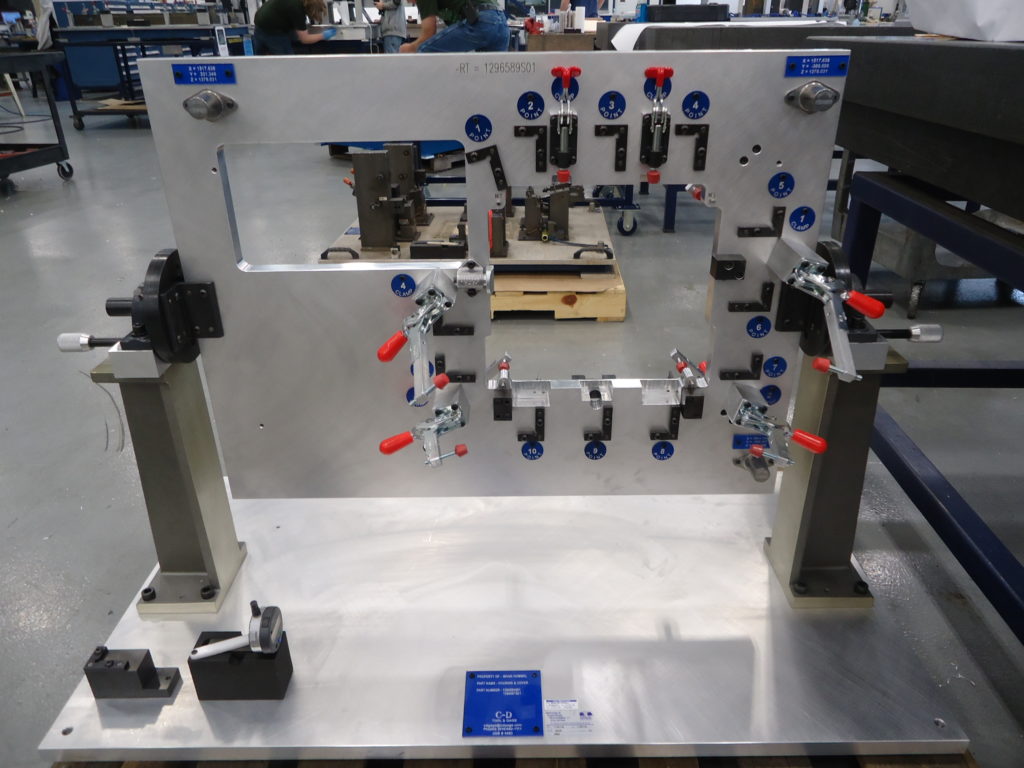

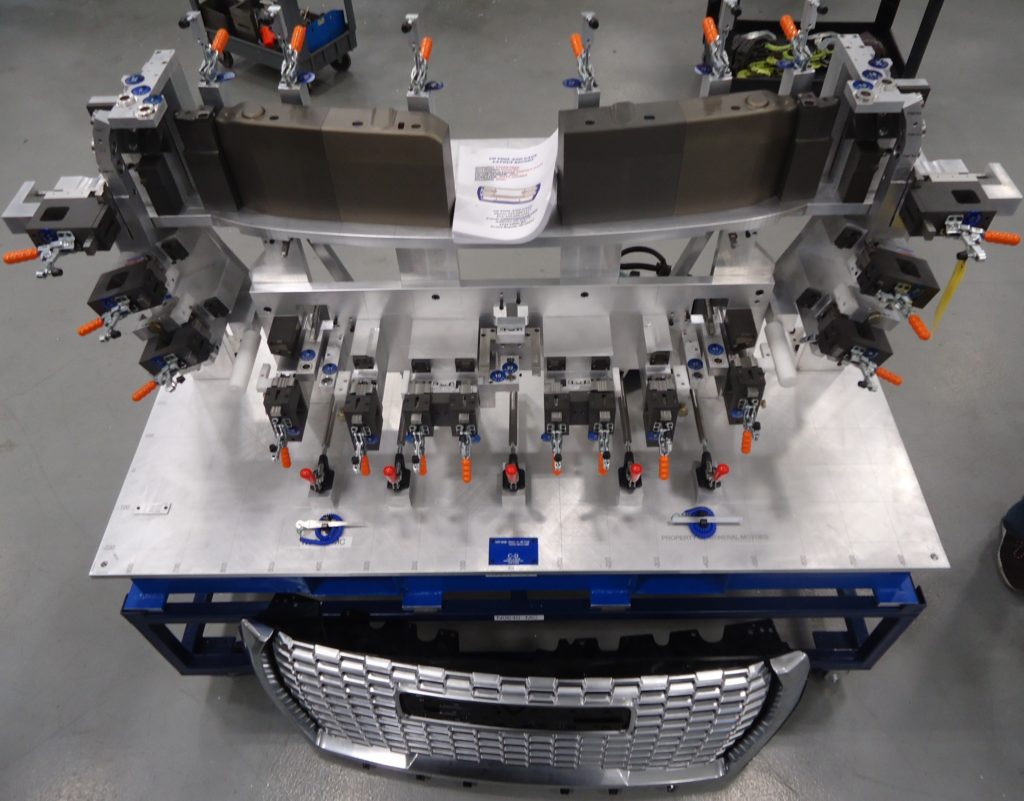

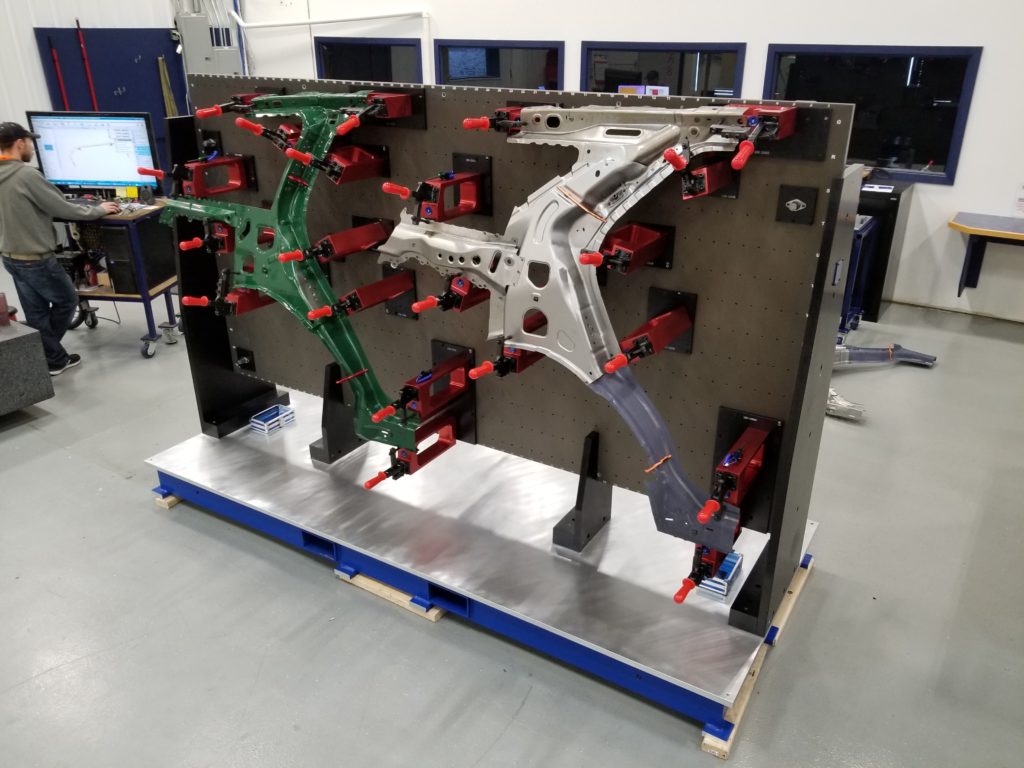

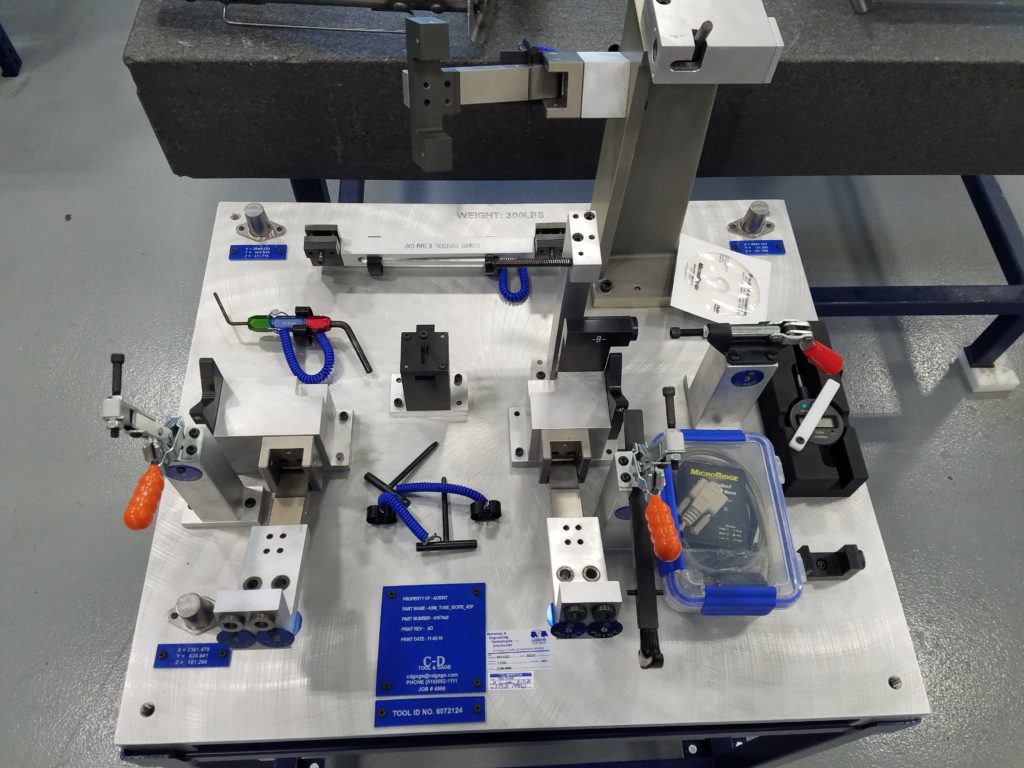

Our team of engineers/designers use Unigraphics (NX Siemens) design software, to design all check fixtures, holding fixtures, scanning fixtures, and special tool needed. These designers will work to ensure all tool designs meet the customer standards as needed.

We also have the capability to translate most CAD files. (CATIA, UG part .prt, iges, .stp, .step, parasolide .x_t, .x_b, .dxf, .dwg, and others). We can also export Adobe Acrobat files in either 2-D or interactive 3-D formats.

We have the ability to do design reviews, or any type of meeting over the web.